It is regularly used in stipulations the location the working internet web page is smal, the flooring is uneven, and the work content material fabric changes freguently. it is suitablefor infrastructure construction, industrial applications, dock loading and unloading, town streets, residential buildings, barns, livestocksheds,airport runways, etc.lt can moreover be used as auxiliaryequmenttorlarde-scaleconstructonmacnineny

Contact Now

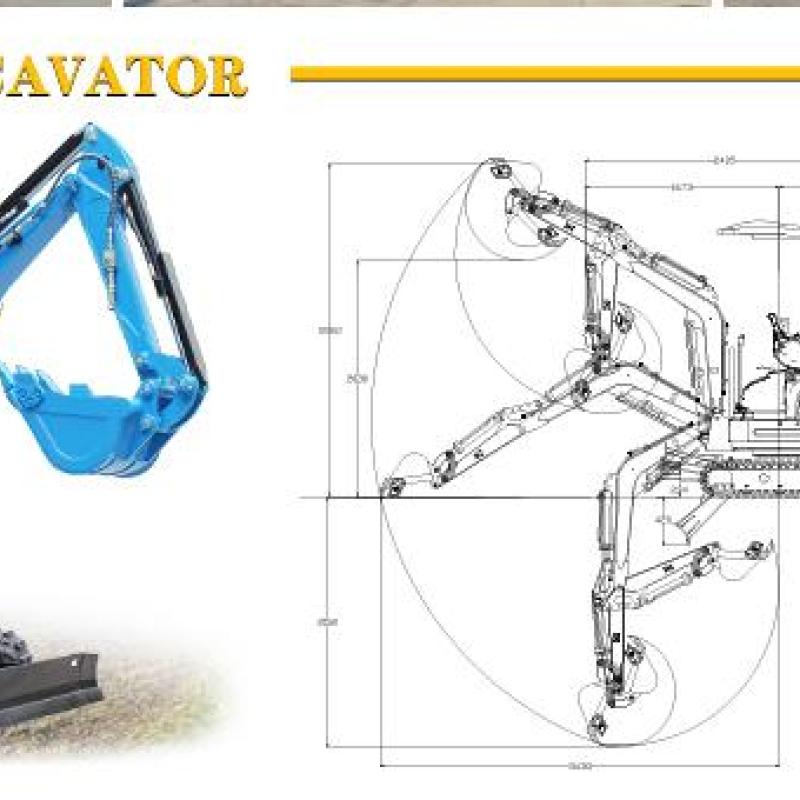

NID330 mini Excavator with Tailless small wing shape and boom-side-shift option, which can be used for narrow-space operation tailless rotation, deflective boom, nice configuration, load pilot working system, changeable rubber track, imported engine, environmental safety general (Euro 5 and EPA 4). Comfortable enclosed cab with 360-degree panoramic view to furnish a comfy surroundings for work.

Contact Now

Rippa 3T Excavator Rubber Track. 1. Chassis and platform: widened and thickened, stable and powerful chassis and platform2. Counterweight: strong cast iron counterweight, higher stability and strengthened forearm design improve the structure, disperse the stress and improve the structural stability and durability3. Strengthen boom and arm: improve stability and durability4. Hydraulic cylinder: the shield, bottom protection device and pipeline are hidden to prevent parts from being scratched and damaged5.

Contact Now

It is often used in conditions the place the working web page is smal, the floor is uneven, and the work content material adjustments freguently. it is suitablefor infrastructure construction, industrial applications, dock loading and unloading, city streets, residential buildings, barns, livestocksheds,airport runways, etc.lt can additionally be used as auxiliaryequmenttorlarde-scaleconstructonmacnineny

Contact Now

rippa NDI 150 large crawler excavatorOne of the outstanding features of the NDI 150 medium crawler excavator is its reinforced frame structure and track system. This design ensures stability and durability, improving work efficiency and allowing the excavator to operate reliably even in the most challenging conditions.

Contact Now

The skid steer loader is a multi-functional and efficient engineering machinery equipment that has a wide range of uses in various fields. The following is an introduction to the main uses of skid steer loaders:1、Construction sites: Skid steer loaders are often used for various earthmoving operations at construction sites, such as excavation, grading, loading, etc.

Contact Now

The Rippa R340 track-mounted hydraulic mini excavator sounds like a capable piece of equipment suitable for working in small terrain and tight areas. It is very important to use structural parts made of stainless steel metal or plastic materials to extend the service life of the equipment. High-quality booms, sticks and buckets help extend the equipment's load-bearing life and ensure the durability of your excavator. Overall, this excavator offers strong overall performance and is suitable for use in a variety of job sites

Contact Now

The Rippa R340 track-mounted hydraulic mini excavator is highly maneuverable and can easily work in small terrains and tight areas. The structural parts of the excavator are made of stainless steel metal or plastic materials, which can extend the service life of the carrier. The R340 excavator is equipped with high-quality boom, stick and bucket, which can extend the load-bearing life of the equipment and ensure efficient work performance. Overall, the R340 excavator has strong performance and is suitable for a variety of workplaces. It is a powerful and durable mechanical equipment.

Contact Now

Rippa L330 Cab Micro Mini Excavator two Ton. The minimal width of the crawler is 1100mm, and the crawler can be prolonged to 1500mm. The hydraulic pilot take care of is greater touchy and clean than the desktop operation. The two-hand operation is bendy and portable, and the motion is touchy and can be completed four at the identical time. It has many benefits such as swing arm, prolonged track, excessive and low speed.

Contact Now

Rippa R308 0.8 ton new micro digger1. Quality assurance: passed the EU CE, ISO quality certification.2. Standard rubber track, optional steel track.3. Eco-friendly: All cover parts are made of metal, durable and recyclable.

Contact Now

NID330 mini Excavator with Tailless small wing structure and boom-side-shift option, which can be used for narrow-space operation tailless rotation, deflective boom, first-class configuration, load pilot operating system, changeable rubber track, imported engine, environmental protection standard (Euro 5 and EPA 4). Comfortable enclosed cab with 360-degree panoramic view to provide a comfortable environment for work.

Contact Now

L330 mini excavator 2 ton digger. Equipped with a hydraulic pilot handle, it is more sensitive and stable than the machine operation, and the two-hand operation is flexible and portable. It has many advantages such as swing arm, extended track, high and low speed, no tail, telescopic track, etc. The hydraulic pump adopts the nine-tooth spline technology, which is more stable. The hydraulic pump shell is made of one-time stamping, which can reduce the internal leakage caused by thermal expansion and contraction.

Contact Now

The 20T excavator uses imported engines and complies with Euro III emission standards. The engine has strong power, sufficient power reserve, energy saving and environmental protection. The ze485E-10 uses an integral molded large section design to further improve the structural parts, reducing butt welding by reducing stress and strengthening and thickening key parts to improve load bearing capacity. Heavy parts, such as bearings, sprockets and track rollers, are specially reinforced.

Contact Now

L330 mini excavator 2 ton excavator. Very cost-effective, equipped with hydraulic pilot handle, more sensitive and smooth than machine operation, flexible and portable for two-hand operation. It has many advantages such as swing arm, extended track, high and low speed. The rotating motor gear adopts spline technology, which transmits large torque and is not easy to damage. The rotating motor gear adopts spline technology, which transmits large torque and is not easy to damage. Increase the oil drain hole to avoid oil leakage.

Contact Now

1.The widened track shoes guarantee low ground pressure, high stability, and powerful traction to fulfill precise horizontal operations.2.The wet type steering clutch and brake can prolong the service life and are interlinked with each other toguarantee the rapid and flexible steeringcontrols by joysticks.3.It can complete the digging, handling, and landfill operations of earthworks and is suitable for the engineeringconstructionsfor roads, farms, waterconservancy projects, municipal projects, and energy projects.4.small hydraulic excavator boasts small size, flexible operation, and favor

Contact Now

The NDI 680 is a powerful, energy-efficient machine. It uses a well-known brand engine with strong power output and excellent fuel efficiency. The dual-speed motor design can improve work efficiency, and it can also respond quickly to emergency conditions.The equipment adopts a sturdy and durable platform design, and the key structural components are optimized to improve the overall reliability.

Contact Now

Rippa Compact Mini Excavator 2 Ton. Equipped with a hydraulic pilot lock, the armrest box can be lifted together to increase the space for getting on and off. It has many advantages such as swing arm, extended track, high and low speed, no tail, telescopic track and so on. The hydraulic pump adopts nine-tooth spline technology, which is more stable. The hydraulic pump casing is formed by one-time stamping, which can reduce internal leakage caused by thermal expansion and cold contraction.

Contact Now

R18-3 PRO is Rippa's new best-selling product. This product is equipped with Kubota diesel generator D902. This engine has excellent design and brings powerful performance, greatly improving work efficiency. At the same time, it has the advantages of low fuel consumption, low vibration and low noise, and is also more environmentally friendly.Ultra-small turning at the tail: Minimize the part beyond the outside of the track when turning, so that the machine can turn safely and reliably.

Contact Now

According to the pressure principle, the grounding area of the track is large, and the pressure generated by the vehicle weight can be effectively distributed to a larger area, so the pressure becomes smaller.

Contact Now

Rippa 0.8 ton smallest excavator crawler hydraulic. This machinery is our company's best-selling model. It is small, flexible, easy to operate, and can work in a narrow field. It is also suitable for orchard planting, trenching, fertilization and weeding. Integrated function, rocker function and telescopic track. Flexible and easy to operate, can work in a narrow site. The small excavator is used for repairing the ground, damaging concrete, and for cable pouring, water pipe laying, planting, river / ditch cleaning and introducing challenges.

Contact Now

Micro Shovel Excavator Rippa 1 Ton. Factory extraordinary layout department, new and updated appearance, very small and flexible. Adopt Kubota engine, high-precision multi-valve, wear-resistant engineering rubber track. The reinforcement arm shape is made of stainless metal or sprayed to extend the provider life. 360° rotation, handy to learn, bendy operation and lengthy provider life.

Contact Now

R319 1 ton excavator. Factory exclusive design department, new and updated appearance, very small and flexible. It adopts Changchai 192F engine, high-precision multi-valve, adjustable blade, wear-resistant engineering rubber track. Strengthen the design arm, stick and bucket, so that the life of the whole machine is longer. The structural parts are made of stainless steel or plastic to prolong the service life. 360° rotation, easy to learn, flexible operation, using steel rails, long service life.

Contact Now

This Vippa model NDI635 crawler loader demonstrates excellent basic performance. It uses a Briggs & Stratton diesel engine with a power of 17 kW/3200 rpm, which provides strong power for the machine.The loader is equipped with a "speed mode adjustment" function, which can automatically adjust the engine speed according to work needs to improve work efficiency.

Contact Now